- Lifting height (underfloor): 185 cm

- Must be installed underfloor (CE-certified)

- Load capacity: up to 3,500 kg

- Galvanised base plate, platforms and housing

- Wheel section over 3 metres (suitable for Multivans)

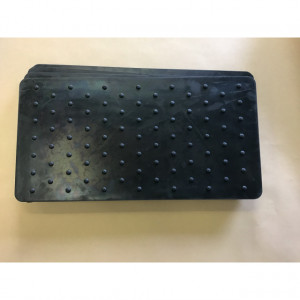

- Acoustic warning system (foot protection)

- Control panel with folding safety covers instead of glass protection panels

- Integrated deflection aid

- High-quality, solid construction

- Compressed air required – compressor necessary

Full-rise scissor lift, Underfloor - KROEMER XX63

As low as

£2,822.52

Availability:

Out of stock

Only %1 left

| Delivery Time | 5-10 Business days |

|---|---|

| Shipping costs | 599 £ |

- 1A processing quality with CE certificate for UVV approval

- Manufactured according to ISO 9001 standards

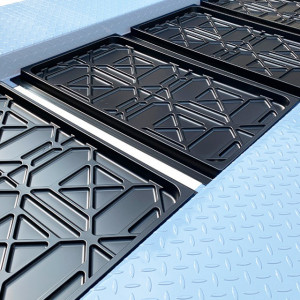

- 4-fold extendable ramps

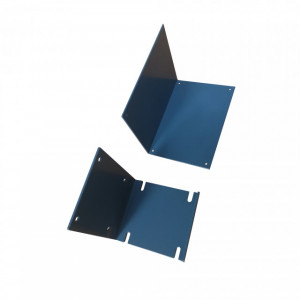

- Includes steel frame (transport safety device) – can also be used as a mounting frame

- Extendable ramps can each support up to 800 kg per side

- Powerful aluminium electric motor with IP54 control unit, aluminium hydraulic motor and metal oil tank

- Two high-performance hydraulic cylinders

- Audible signal and CE stop during lowering to prevent foot injuries (foot protection system)

- Overload protection via pressure relief valve

- Bolts and screws hot-dip galvanised

- High-quality DUPONT powder coating for maximum durability

- Compressed air compressor required

- Our products are covered by Allianz product liability and public liability insurance

With a maximum lifting height of an impressive 1,850 mm and a lifting time of just 50 seconds, a Kroemer scissor lift is an essential piece of equipment for almost all maintenance work on tyres and lower vehicle components. Professional environments such as workshops and tyre service centres place particularly high demands on lifting platforms – and we at Kroemer have met these requirements with our specially designed professional lift. Even ambitious hobby mechanics appreciate the XX60 model, as it can be installed completely flush with the floor (0 mm ground clearance).

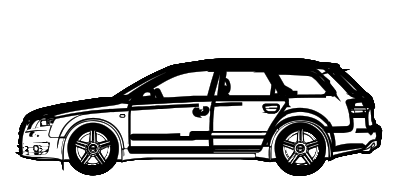

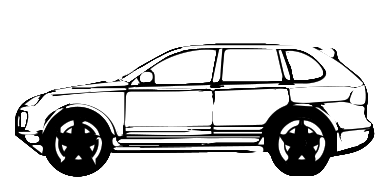

With its extendable ramps, the XX63 scissor lift is particularly suitable for cars with a long wheelbase, SUVs, and T6 models with a standard wheelbase.

Does your vehicle have an extended wheelbase? No problem with Kroemer! Thanks to its four extendable, extra-wide drive-on ramps (2,435 x 540 mm), this professional scissor lift offers outstanding flexibility. Even your most demanding customer’s Porsche can be lifted within seconds. With a newly reinforced movable scissor design, the lift is also perfectly suited for SUVs.

Our engineers have developed this professional scissor lift with durability and longevity in mind. Lubrication nipples are installed on almost all moving joints for smooth operation and reduced wear. One of the most common causes of failure in scissor lifts is corrosion in compressed air cylinders — that’s why Kroemer lifts come with an integrated oiler as standard, effectively removing water from the compressed air circuit. Another weak point in conventional lifts is hydraulic cylinder leakage. Kroemer offers optional double-walled compressed air cylinders, reducing maintenance needs and significantly improving reliability.

The newly designed oil-immersed motor ensures exceptionally quiet operation. Its low-noise performance makes it gentle on the ears, even during daily workshop use.

No more paint scratches or poor workmanship! Your new professional scissor lift from Kroemer features a premium-quality DUPONT® powder coating, expertly applied for maximum durability and a flawless finish.

At Kroemer, we don’t source our hard chrome-plated hydraulic cylinders from low-cost workshops. This results in reduced susceptibility to faults and lower maintenance requirements. And if anything ever stops working, you’ll always find the right spare part directly in our shop — quick, reliable, and hassle-free.

NOTE: To ensure trouble-free operation of the lift and to avoid damage to the vehicle/ceiling, the room height must be at least 3.20 m or 3.50 m for mid-rise scissor lifts and 4.20 m or 4.50 m for full-rise scissor lifts (depending on the vehicle and lift height). Please refer to the technical drawing for the dimensions of the lift.

*The steel frame is a transport safety device and may show scratches and damage, but these can be easily repaired by a specialist.

| SKU | XX63 |

|---|---|

| EAN-Code | 0703441952357 |

Write Your Own Review

Underfloor Full-Rise Scissor Lift

230V or 400V Electric Motor – Powerful and reliable

Hydraulic Unit – Smooth and consistent lifting performance

English operating manual and inspection log for UVV safety approval available for download.

Invoice provided with VAT clearly stated.

Two mounting frames are included for transport safety and can be used for installation if required (foundation plan included).

Not Included in Delivery:

-

Air Compressor: A compressor with 8–10 bar pressure is required.

-

Hydraulic Oil: Not included – available as an optional extra (fill capacity: 20 litres).

-

Vehicle: Not included.

-

CE Plug: Can be ordered as an optional accessory.